There are a lot of solutions on how to equip a recreation area near the house. You need something that is convenient, inexpensive, stylish and reliable at the same time. These are the gazebos made of polycarbonate, combining lightness and airiness with amazing durability. They can also be very effective, and to prove it, we share design ideas with you!

Advantages and disadvantages

The most durable of all transparent materials can confidently be called polycarbonate. It easily tolerates heat and frost, sharp temperature fluctuations, is not afraid of moisture, does not burn and does not collapse at temperatures up to 160 degrees. Especially durable sheets with a honeycomb structure are suitable even for stationary buildings.

The material is not afraid of fungus, mold and parasites, which is important when building a gazebo. Shockproof characteristics are dozens of times superior to ordinary plastic and even more so glass. If somehow managed to break the sheet, the fragments are not sharp and safe.

Polycarbonate is easy to cut and fasten, only you need to isolate all ends with plugs. Thermal washers are used for installation, which compensate for expansion when heated. The material can be bent and shaped if you want a gazebo with a domed roof or shaped elements.

Keep in mind that it is hot and stuffy in summer in a gazebo made of solid polycarbonate, so don't forget about ventilation. Soundproofing during strong winds and rain also leaves much to be desired. The roof must withstand the operational loads, but this is easily solved by purchasing more durable sheets.

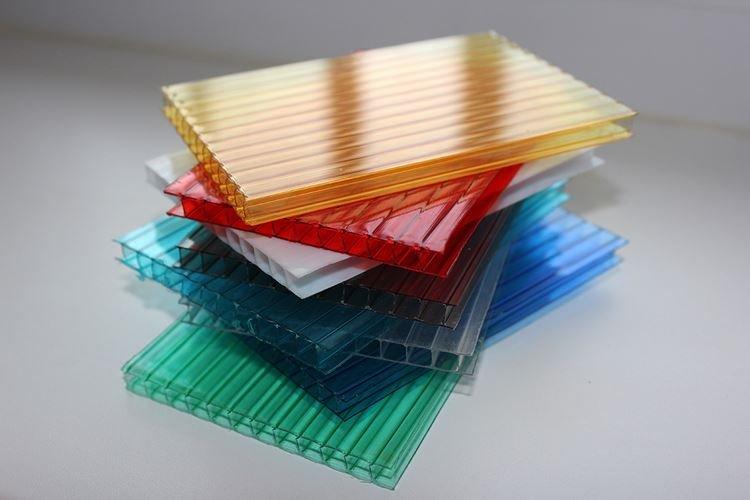

Types of polycarbonate for gazebos

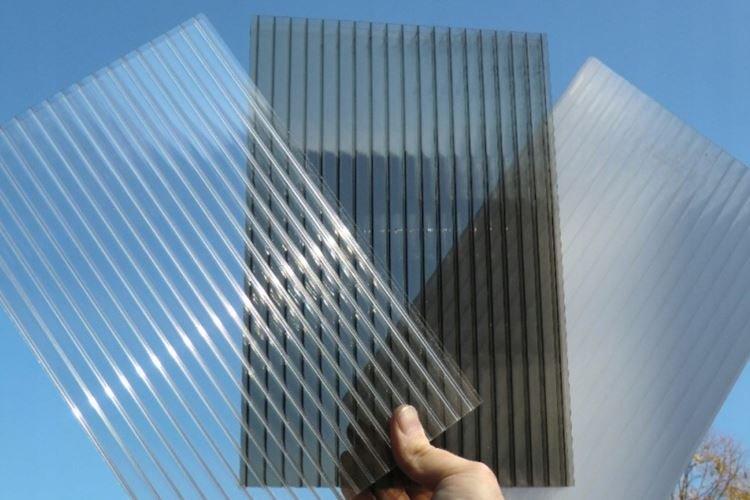

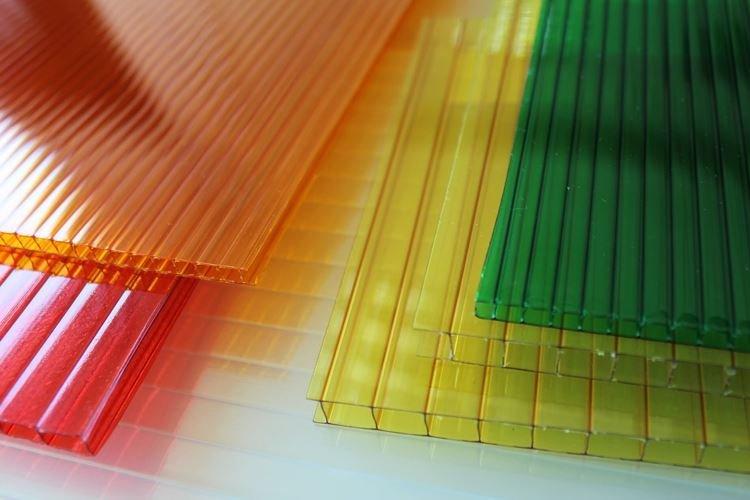

Cellular polycarbonate is stronger, lighter and cheaper, so it is well suited for the load-bearing and structural parts of the gazebo. It got its name for its characteristic cellular structure. Two- or three-layer sheets with a thickness of 0.8 cm serve up to 50 years.

Monolithic is outwardly indistinguishable from glass, but much stronger and lighter. It can be smooth or textured, so it works well for decorative items. In order for the material to withstand loads better, a minimum thickness of 0.5 cm is needed, and this is much more expensive.

DIY polycarbonate gazebo

In any case, you will have to combine polycarbonate with other materials for the frame. Metal is the fastest and easiest option, because it is strong, durable and unpretentious. We will tell you about him!

Foundation

If you need a reliable stationary building with supports made of bricks or heavy woods, a foundation is a must. For massive closed gazebos, a monolithic base is suitable, but for semi-closed ones, a lightweight tape or columnar is enough.

If you want a gazebo with a stove or barbecue - the foundation for them is laid separately, with a layer of heat-resistant brick on top. Lightweight polycarbonate gazebos will cost only metal supports from pipes, without a foundation. They are not so durable, but they will do quite well for several seasons.

Frame for the gazebo

For the frame, metal pipes and corners are needed, and for the connection - a welding machine, and this is the only difficulty in the process. A light gazebo will do without a foundation - only on supports. To do this, drill meter-long depressions with a diameter of about 10 cm.

Fill a cushion of rubble with sand with a thickness of about 20 cm inside. Set the supports strictly vertically and check the level all the time. To prevent the structure from moving before the concrete hardens after pouring, make spacers from a bar. All connections are reinforced with welded metal corners.

Polycarbonate cutting

For cutting polycarbonate, choose tools with fine teeth so that the sheet does not crumble or crack. If the walls are completely polycarbonate, take transparent sheets - they do not expand so much when heated.Perform installation work on a dry, windless day, because the material is very light.

Installation of polycarbonate

First assemble the roof on the ground, and do not forget to treat it with an anti-corrosion primer. Pour a screed on the floor and then lay it with boards or tiles. Sheathe the gazebo with polycarbonate sheets last, using self-tapping screws with thermal washers. When drilling holes, back off from the edge by 3-4 cm, and seal the joints with silicone.

Polycarbonate gazebos - photos and ideas

We have already talked about the main characteristics and advantages of polycarbonate for gazebos. And now we are sharing several interesting options that you can build from it.

Open gazebo made of polycarbonate

This is the lightest construction with no walls at all or with a minimum of them. Polycarbonate is needed for the construction of a roof from rain and bad weather. Therefore, choose sheets that are stronger and thicker, and best of all - with a protective coating against ultraviolet radiation.

Closed gazebo made of polycarbonate

This is already a full-fledged closed "house" in which you can hide from the rain and wind. Experiment with colored and textured sheets or combine polycarbonate with other materials. For example, with brick supports and decorative wrought iron elements.

Mobile gazebo

Unlike stationary structures, which are installed on the site once and for all, mobile ones can be carried. And lightweight thin polycarbonate suits the task best. For the frame, use a metal profile, but instead of dug in supports, you need a support frame from below.

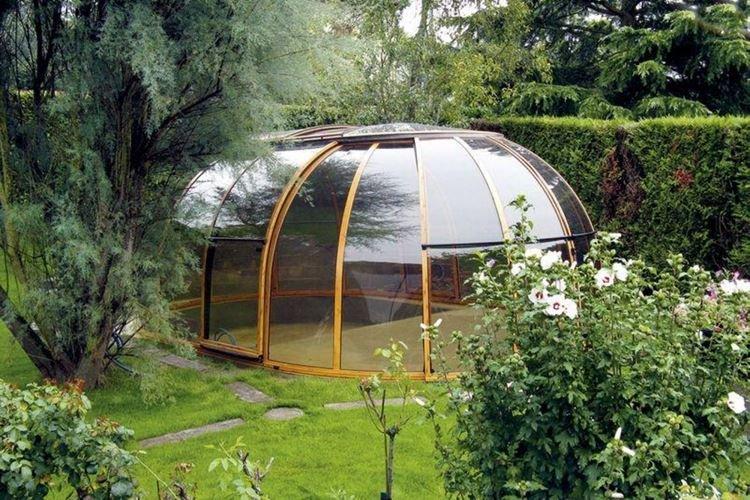

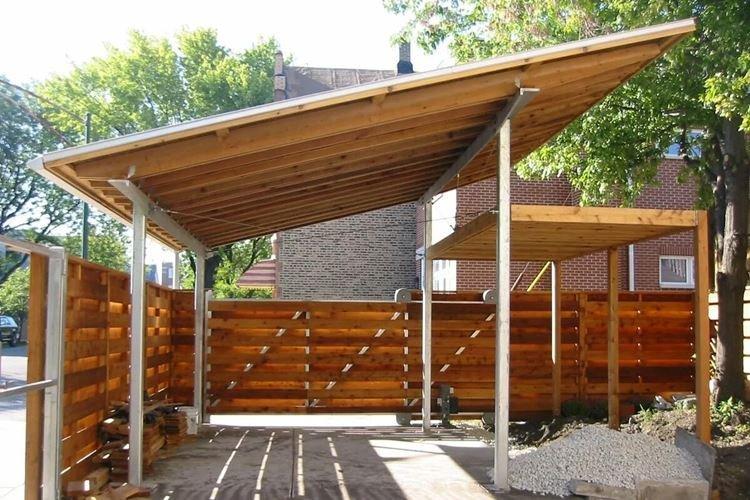

Pergola with wooden frame

The combination of natural wood with modern polycarbonate is the perfect choice for modern eclectic styles. Such a gazebo is beautiful, environmentally friendly and will fit into any exterior or landscape composition. Just do not forget to take care of the tree, soak it with antiseptics and cover it with a moisture-repellent varnish.

Polycarbonate gazebo with barbecue

The main thing here is to properly equip the area for a barbecue or stove, and to take the gazebo itself at least 5 m from the house and other buildings. You need a monolithic concrete foundation with a thickness of 40 cm and a refractory finish: oven brick, tile or stone.

Gazebo with a pitched roof

This is the simplest option, for which it is enough to sheathe a straight frame with straight sheets. By the same principle, awnings and gazebos are made, which are adjacent to the wall of the house. It is desirable that the angle is more than 15 degrees and water and snow do not accumulate on the surface.

Gazebo with a pitched roof

Two-, four- and even six-pitched roofs for gazebos are made according to the same principle. The main thing is to cut the polycarbonate correctly and treat all joints well with silicone sealant. Technically, the process is not particularly difficult to install a pitched roof, but much longer.

Arbor with arched roof

For such a roof, polycarbonate sheets need to be bent with an arc for attaching to the rafters. Honeycomb sheets are bent down with honeycombs - this way they are stronger, and moisture from condensation will not accumulate inside. You definitely need a strong frame to attach polycarbonate around the perimeter, and wide sheets also in the middle.

Gazebo with a domed roof

At first glance, it seems that it is almost impossible to do this on your own. In practice, it is possible to bend polycarbonate even without heating, but be sure to take into account the minimum radius. It depends on the thickness of the sheet: for example, for 4 mm it is 700 mm, and for 25 mm it is already 5000 mm. Unlike honeycomb, monolithic sheets can be bent in both directions.